What is reality capture in construction, and what are its benefits, applications, and limitations? We’ve developed this helpful guide to answer these and other questions because we know it can be challenging to keep up with the latest innovation and technology in the construction industry. Let’s dive in.

What is reality capture used for in construction photo documentation, and how does it work?

Reality capture is one of today’s most innovative technologies transforming construction, making short work of processes like jobsite photo documentation—historically a tedious, time-consuming activity. Reality capture solutions offer a welcome replacement for manual methods by letting builders digitally capture, share, and analyze real-world jobsite conditions to move faster and make smarter decisions. These solutions can leverage laser scans, drone images, smartphone photos, or, in the case of OpenSpace, high-resolution 360° images. Historically, reality capture consisted of capturing 360° images with laser scans, but OpenSpace led the way in democratizing reality capture with a more cost-effective and efficient way of capturing with 360° cameras mounted on a person’s hard hat during regular site walks. Once the capture data is uploaded to the cloud, project stakeholders can virtually walk through the jobsite by accessing the images from their desks or anywhere in the world to see site conditions in near-real time and identify issues quickly.

Using a reality capture platform like OpenSpace, small and large builders alike can significantly streamline many of their processes to generate significant cost savings on single projects or multiple projects across an entire company. From reducing travel by as much as 50% and improving communication to strengthening project management capabilities and enhancing QA/QC, companies using reality capture are seeing a significant return on their investment.

What is the difference between reality capture and site capture?

Reality capture is essentially the same as site capture or jobsite capture. The term “reality capture” has been around for quite some time, often used to refer to very high-fidelity 3D captures using laser scanners or LiDAR. However, the lower cost, ease of use, and frequency of capture that OpenSpace enables make the technology an attractive, newer alternative to the more traditional means of capturing.

We prefer “reality capture” as a way to think about OpenSpace technology because our solution goes beyond these inputs to let you capture the way you want, be it with cameras on drones (with support for the Insta360 Sphere), 360° cameras, iPhone and Android mobile phones, LiDAR scanners, and even robots like Spot the dog. Moreover, reality capture enables builders to create a highly accurate and comprehensive digital replica (or digital twin) of physical spaces and structures in near-real time, so closely simulating reality that you don’t even need to be on a construction site to see the latest conditions or track progress.

What is reality capture?

Reality capture refers to the process of digitally documenting and replicating the physical world, often utilizing technologies like 3D scanning, photogrammetry, LiDAR, and drones. It involves capturing detailed, high-resolution data about real-world objects, environments, or scenes and converting this data into digital models or representations. Reality capture has applications in numerous fields, including architecture, construction, archaeology, and virtual reality. It enables precise measurements, visualizations, and simulations, making it invaluable for design, analysis, and decision-making. Reality capture not only enhances our understanding of the physical world but also empowers industries to innovate, streamline processes, and create experiences in virtual and augmented reality environments.

What is OpenSpace reality capture?

OpenSpace is the global leader in reality capture and AI-powered analytics for builders with projects of all shapes and sizes, whether a quick renovation or a multi-year megaproject. With OpenSpace, you can quickly and easily capture a comprehensive visual record of your construction site to verify work-in-place, simplify dispute resolution, and keep teams accountable. Our AI-powered computer vision and analytics tools give your team the visibility and insights they need with the power to compare BIM to as-built, automatically track progress, and stay on schedule. Our powerful integrations and Field Notes feature help you streamline workflows to enable better communication, smarter resource allocation, and faster decisions. More than 100,000 users in 91 countries rely on OpenSpace to get the job done on time and on budget, every time.

What are the best ways to integrate reality capture into existing construction project workflows?

Naturally, reality capture is used for the process of documentation. It serves as a foundation of images and data that represent the state of how something was built at a specific point in time. Beyond documentation, reality capture can be integrated into construction project workflows through coordination and tracking progress.

Here are some common ways that builders integrate reality capture into existing construction workflows:

- Using the capture data as reference material during OAC meetings

- Supplementing the question or solution to RFIs

- Leveraging capture data to compare site conditions to design intent for quality control purposes

By viewing reality capture data, builders can make informed decisions without having to go to the jobsite. This improves the speed of communication between different stakeholders, allowing the project to progress efficiently.

What are the limitations of reality capture, and how can they be addressed?

There are a few limitations of reality capture, including time, logistics, cost, quality, and data management. Let’s take a closer look at each.

- Time: Within a project, there will only be a certain amount of time that someone can dedicate to performing reality capture on the jobsite. This can lead to incomplete data for areas that were not able to be captured.

- Logistics: There has to be some type of organization around the personnel allocated to performing the reality capture and when and where the work is being done. Depending on the type of reality capture being performed, certain areas of a project may not be accessible at the scheduled or desired time. If a structured process cannot be put in place, this could lead to limited data for the project team to work with.

- Cost: Reality capture solutions are not priced the same way, and approaches can vary depending on the sophistication of the equipment needed. Some solutions require large initial investments that are only used periodically, so it can take a while before achieving a known return on investment.

- Quality: Depending on the technology, time of day, or existing environment at the time of capture, the quality of the data can vary.

- Data management: Reality capture produces large amounts of data, so all that data will need to be effectively stored, processed, and managed

There are various ways to address these limitations, including the following strategies:

- Find a reasonably priced reality capture solution that can be used frequently.

- Choose a reality capture solution that can process and return the captured data for analysis within a timeframe that still makes the data usable.

- Use a solution whereby operating the equipment is easy enough that anyone on the project can use it.

- Create and follow a capture schedule that field teams agree to and can help coordinate timing and area access.

What are the costs associated with reality capture, and how can ROI be calculated?

There are two ways to look at costs associated with reality capture: the cost of the technology itself and the significant cost reductions that the technology creates.

When investigating the cost of reality capture solutions, start by considering your current documentation spend, either the technology you’re currently using or the dollar value of your team’s time consumed by manual methods. Pricing for reality capture software may be determined based on the size of a project site, the type of software or features required, or the frequency of captures.

By way of example, OpenSpace provides flexible pricing based on the products you need and the amount of construction you’re doing. OpenSpace pricing scales with your business to match anything from a quick renovation project to a multi-year megaproject or global portfolio, and annual subscriptions cover unlimited captures and users.

In terms of cost reductions, builders can achieve significant savings in every stage of construction and beyond using a reality capture solution like OpenSpace. Here are just a few ways you can expect to save time and money with OpenSpace:

- Reduced travel – Stakeholders can walk through sites virtually, and teams can monitor progress remotely, so teams no longer need to travel to jobsites to see the latest conditions, spot issues, or verify work completed.

- Fewer destructive investigations and less rework – There is no need to open up walls, cut into ceilings, and demo slabs when you can effectively see right through them to understand what’s installed.

- Discounted insurance premiums – Carriers recognize that reality capture creates greater visibility, which in turn reduces risk and uncertainty in construction and simplifies claims. In return, some firms like Shepherd offer reduced premiums to builders that use this technology.

- Faster and more robust site documentation – When you add up the hours your team spends every week taking manual photos, the number can be staggering. Adopting a passive, automated method drastically reduces the time spent on documentation while also delivering far greater detail and coverage of your jobsite.

- More effective field notes and RFIs – Using a solution like OpenSpace that automatically maps field notes to the floor plan can speed up core processes like change orders, RFIs, and quality assurance and improve coordination in just a couple of clicks.

- More efficient image organization – Organizing, searching for, and sharing images with stakeholders is a time-consuming and seemingly never-ending effort. Using a reality capture solution, teams can easily find the right images and send them to stakeholders in a matter of a few clicks.

- Improved safety and QA/QC inspections – Reality capture provides a complete digital record of the jobsite, which makes it far easier to conduct safety inspections, submit safety reports, and do QA/QC on completed work.

- Better closeout package creation – Using reality capture, teams can quickly compile 360° images into a comprehensive closeout package for facilities teams to make it easier for them to maintain the building over its lifecycle.

How can reality capture be used for quality control and inspections?

In the past, QA/QC teams would travel to project sites to take photos with their phones in order to fulfill their inspection requirements. And while quality control has traditionally occurred on-site, it is yet another core function that can be completed remotely using the latest technology. Today, companies are increasingly leveraging visual data for quality control and inspections and to identify safety hazards. Using reality capture, teams can simply strap a 360° camera to their hard hats and walk the site, allowing them to focus as OpenSpace captures in the background and automatically pins imagery to the project plan.

For example, teams might see a balcony where a railing has not been installed, causing a safety issue, or a hallway where a ladder has been left out. Moreover, thanks to 360° reality capture, this important work can now be part of the remote site management process because the incredible detail of the 360° images lets them identify any issues or discrepancies just as easily as if they were walking the site in person. OpenSpace customers report improved safety, reduced risk, and avoided rework since they can spot issues sooner, thanks to their improved quality control capabilities. The technology equips teams to quickly provide updates in near-real time and conduct virtual site walk-throughs, providing all project stakeholders the opportunity to review progress, track quality control and review various inspections.

How does reality capture work with BIM 360 and project management software? How does reality capture work with Navisworks and 3D model software?

Reality capture works with BIM 360 and top construction project management software such as Procore, PlanGrid, and Autodesk Construction Cloud by providing a quick way to ingest large amounts of field data and pushing that data into a workflow within these systems. Ideally, it would increase the efficiency of communication between the field and the office.

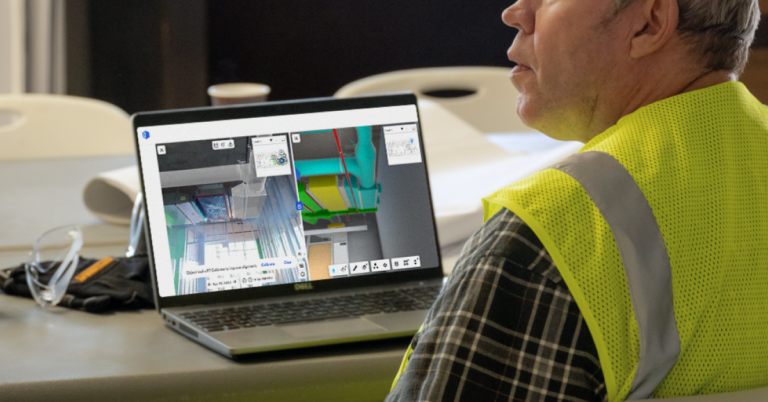

Reality capture works with Navisworks/3D model software by providing a view into what is actually happening on-site. Navisworks is a program in which multiple models can be combined into a “federated” model. Within Navisworks, it is common practice to run clash detection analysis on the combined model. This usually takes place during the design phase in order to limit the number of clashes that end up happening during the build phase. The captured data that reality capture provides can be compared to the federated model as this represents the design intent. This comparison provides a way to visually see discrepancies that can then be called out and pushed into a project management system to be resolved efficiently.

What types of reality capture technologies are available in construction?

There are numerous reality capture technologies in use by the construction industry today, including:

- Laser scanning: Laser scanners use lasers to capture millions of data points on an object or environment, creating a highly accurate point cloud that can be used to create 3D models.

- Photogrammetry: Photogrammetry uses photographs taken from multiple angles to create a 3D model of an object or environment. The software analyzes the photographs to identify common points and calculates the distance between them to create a model.

- LiDAR (Light Detection and Ranging): LiDAR works by emitting laser pulses and measuring the time it takes for the laser to bounce back to the sensor. This data is used to create a 3D model of the object or environment.

- Structured light: Structured light scanners use a projector to project a pattern of light onto an object or environment. The scanner then measures the distortion of the pattern to create a 3D model.

- Thermal imaging: Thermal imaging uses infrared technology to capture temperature data from an object or environment. This data can be used to create a thermal map of the object or environment.

- Sonar: Sonar uses sound waves to create a 3D map of an underwater environment. The sonar emits sound waves and measures the time it takes for them to bounce back to the sensor.

What are the benefits of using reality capture for documenting and managing construction jobsites?

Reality capture is a process of creating a 3D model of a physical object or environment using a variety of sensors, including laser scanners, cameras, and drones. This technology can be used to document and manage construction jobsites in a number of ways, including:

- Creating as-built models: Reality capture can be used to create accurate as-built models of construction sites, which can be used to track progress, identify potential problems, and resolve disputes.

- Planning and scheduling: Reality capture can be used to create 3D models of proposed construction projects, which can be used to plan and schedule the work more effectively.

- Quality control: Reality capture can be used to inspect construction work for quality assurance purposes and to identify potential defects.

- Safety: Reality capture can be used to create 3D models of construction sites, which can be used to identify potential safety hazards and develop safe work procedures.

- Communication: Reality capture can be used to create 3D models of construction sites, which can be used to communicate with stakeholders, such as clients, subcontractors, and regulatory agencies.

Reality capture is a powerful tool that can be used to improve the efficiency, accuracy, and safety of construction projects. The benefits of using reality capture for documenting and managing construction jobsites include:

- Accuracy: Reality capture is a very accurate way of capturing data, which can lead to more accurate as-built models, plans, and schedules.

- Efficiency: Reality capture can save time and money by automating many of the tasks that are currently done manually, such as as-built surveys and quality control inspections.

- Improved decision-making: Reality capture can provide decision-makers with a more complete and accurate picture of the construction site, which can lead to better decisions.

- Reduced risk: Reality capture can help to identify and mitigate risks, such as potential safety hazards and schedule delays.

- Improved communication: Reality capture can help to improve communication between stakeholders, which can lead to a smoother and more efficient construction process.

What are some best practices for using reality capture for construction project management?

- Set a capture schedule and capture each level frequently or at least once a week.

- Use the reality capture solution as a way to view the project during any and all meetings as a form of visual communication.

- Leverage the data captured by incorporating it into day-to-day workflows, such as sending an email, filling out documents in project management platforms, or validating change orders and pay applications.

Does reality capture help with site walks, and how does machine learning enter into it?

Yes! 360° reality capture helps simplify common processes and workflows, especially site documentation. Using OpenSpace, it’s easy to capture your jobsite. Machine learning is how computers find patterns and solutions without specific instructions. Machine learning algorithms create a mathematical model based on training data to predict future results without being explicitly programmed to perform the task. Our Vision Engine uses each capture and walk track as a training dataset. Every time you walk the site, the Vision Engine learns a bit more about the 3D environment you are in and can align and map the images faster and more accurately. The more you walk your site, the more the Vision Engine learns.

Get more information about how to walk your site with OpenSpace in our support article and this free eBook, The 5-Minute Guide to Construction Photo Documentation.

How can reality capture be used for building information modeling (BIM)?

Reality capture, such as laser scanning, can help build a model representation of the existing conditions with a high level of accuracy. In some cases, the point cloud generated from these scans can serve as the structural background to which different systems can be routed through during the BIM coordination process.

How does OpenSpace reality capture support lean construction principles?

Originally based on principles of lean manufacturing, lean construction has evolved into a powerful way to deliver projects as efficiently as possible. Thanks to rapid advances in construction technology like 360° reality capture, lean projects are becoming even more efficient, positioning teams to deliver better results for their clients. Reality capture technology like OpenSpace helps construction companies adhere to lean principles by providing teams with an independent source of truth to work from and hold one another accountable—while also unlocking new operational efficiencies, providing greater visibility into the progress of work, and helping sustain improved communication.

Using reality capture, teams have a faster response time to conditions in the field, greater day-to-day control over how resources are allocated, and a more collaborative way of sequencing tasks for better flow. Teams applying lean principles aim to avoid the “eight wastes,” which are: transportation, inventory, motion, waiting, overproduction, overprocessing, defects, and skills. In order to avoid these eight wastes, construction teams are using best practices and emerging technologies like reality capture to collaborate more effectively.

Specifically, OpenSpace helps companies deliver lean projects by minimizing the need for travel, avoiding rework and destructive investigations, reducing waste, and creating new sources of operational efficiency, which in turn enables better scheduling, progress tracking, communication, transparency, accountability, and coordination.

To help you evaluate the potential impact of a reality capture solution on your company’s operational efficiency and competitiveness, we’ve published a whitepaper, The Real Value of Reality Capture: Understanding the Business Impact for Builders, which includes examples and first-hand accounts from several top builders across different sectors, a checklist for choosing the right solution, and a customizable ROI calculator to estimate the time and money you can save using OpenSpace reality capture—and the new business you can generate.

Do you have other questions we didn’t cover? Could you use some expert guidance to start using an automated 360° photo documentation solution? Let’s chat and explore how OpenSpace can help you achieve your goals.