With a company history of more than 100 years and over 9,000 employees worldwide, Exyte has become a global leader in the design, engineering, and delivery of ultra-clean and sustainable facilities for high-tech industries. With cutting-edge expertise, the company serves clients in the sophisticated markets of semiconductors, battery cells, pharmaceuticals, biotechnology, and data centers. Exyte offers a full range of services from consulting to managing the implementation of turnkey solutions with the highest standards in safety and quality to its customers worldwide.

The challenge

Martin Wenz has been with Exyte for ten years as Technology Manager and Modular Expert. Among other things, he takes care of bringing new technologies to the site with the aim of increasing efficiency across teams. He became aware of OpenSpace through a customer and is now directly using the solution for a joint new building project.

The 5-storey building with a total of 7,500 square meters is a challenge not only because of its technical specifications. The Exyte team has only 24 months to complete the project. “Every possible gain in time is a gain for the project,” says Martin. To implement the Ultra Fast Track project on schedule, the team relies, among other things, on digital site capture and progress tracking with OpenSpace.

The solution

According to Martin, using 360° reality capture for site documentation is a significant advancement for the team. Before OpenSpace, construction progress was often documented manually. Every week, a planner went on-site to check how much was built and where, and manually entered this information into the project schedule.

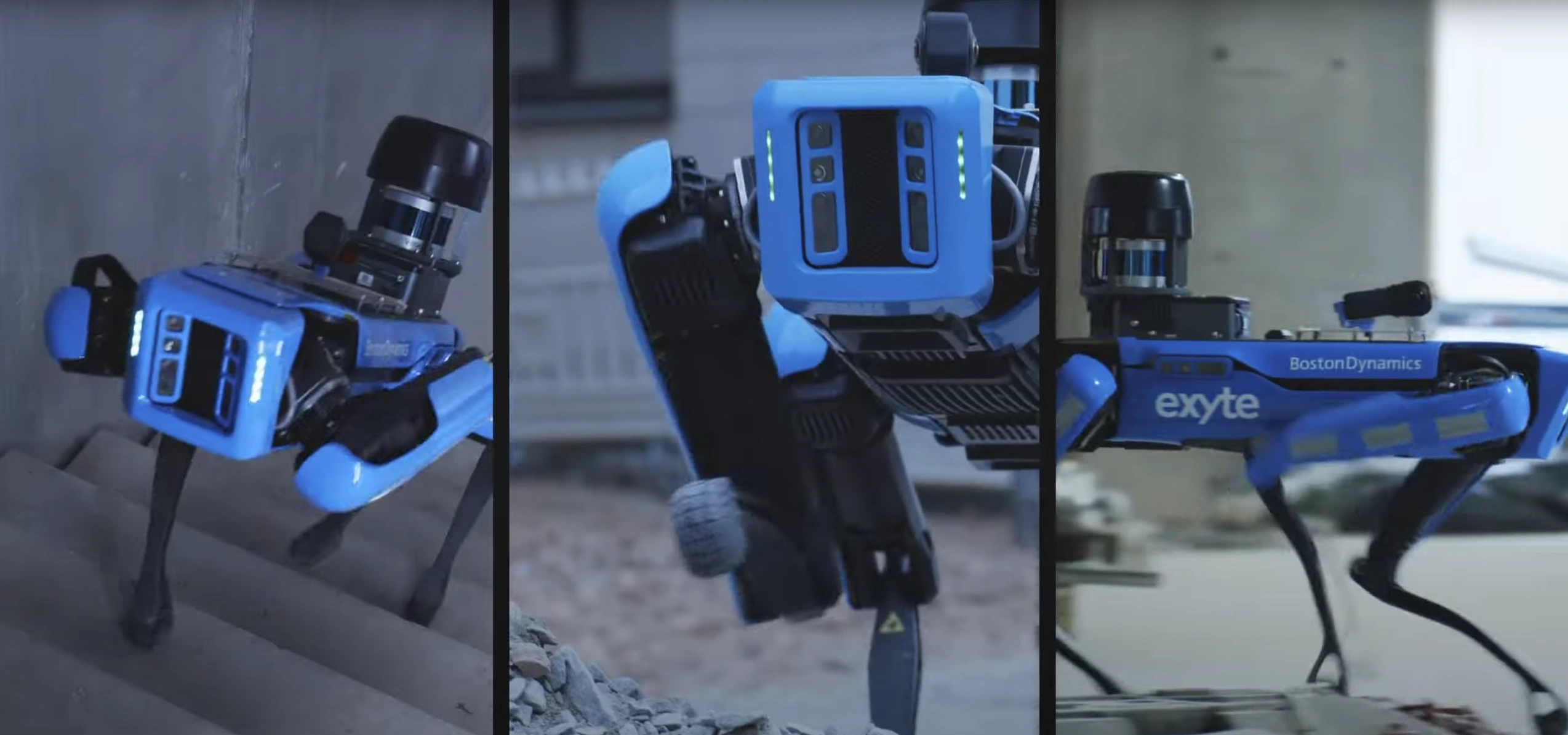

With OpenSpace the team now creates a digital capture of the project–every day. When they first started, the site manager himself walked the construction site with a 360° camera mounted on his hard hat. In the meantime, this task is partly taken over by a robot dog from Boston Dynamics. “It’s normal now for someone to walk through the construction site with a robot dog and camera,” says Martin.

On the current project, OpenSpace Track is being utilized alongside OpenSpace Capture to also streamline the monitoring of construction progress. OpenSpace Track extracts relevant data from Exyte’s 3D model, including information about planned objects and quantities such as walls, electrical components, and pipelines. By regularly capturing the site, the software automatically identifies which elements have already been installed and which elements are still missing. This information is then made visible both in the floor plan and in the form of progress charts and schedules on the OpenSpace platform.

Whether site manager, designer, engineer, safety team or client–on the current project, OpenSpace is the central source of information for everyone involved. And that is precisely why it is so efficient.

It’s normal now for someone to walk through the construction site with a robot dog and camera.

The results

Especially for teams that are open to new technologies, OpenSpace is a must-have, according to Martin. For Exyte, the daily, seamless documentation offers clear benefits.

Improved safety

Fewer site visits

The design team is based in the office in Stuttgart, however the current project is hundreds of miles away in Saxony-Anhalt. Thanks to OpenSpace, everyone still has an overview of what is happening on-site without having to be physically there. “Our architect is always in OpenSpace,” Martin says. This saves both internal stakeholders as well as the client avoidable trips to the construction site.

Improved safety on the construction site

A construction site is always also a safety area. According to Martin, it is already a big advantage that relevant stakeholders need to be on-site less often. Training for new team members also takes place virtually before moving on-site. In addition, the safety team uses OpenSpace Field Notes to report and track so-called Safety Behaviour Observations (SBOs). These are usually created virtually from the office and then implemented by the team on-site.

Shorter, direct communication channels

Questions such as “Is this part of the building already finished?” often ended up with Martin or with the site manager. Since OpenSpace is a central source of information, stakeholders can now find answers to their questions directly in the software. Martin’s conclusion: “That’s also more relaxed for me, when I don’t have to send the site manager on-site every time to check.”

Faster decisions

Especially in certain discussions about where new installations should be placed, there is no longer a need for long deliberations. “In some cases, discussions about possibilities to install things have been extremely shortened,” Martin says. Even during the alignment meeting, the most recent capture can simply be accessed, and it can be checked whether there is enough space at the planned location or not.