Linxon, a joint venture between AtkinsRéalis and Hitachi Energy, delivers critical power infrastructure that supports the global energy transition. Operating across AMEA, Europe, and the Americas, the company combines EPC project delivery expertise with advanced electrical engineering to build substations and grid solutions for utilities, power generation, railway, data centers, and battery energy storage systems.

As the demand for low‑carbon, resilient power systems grows, Linxon continues to embed digital tools that improve visibility, efficiency, and collaboration. OpenSpace’s AI‑powered Visual Intelligence Platform is an important part of this digital transformation.

Driving sustainable, data‑led impact

Digital workflows are central to how Linxon plans, builds, and manages infrastructure projects. Through automated data capture, and AI‑supported analysis, teams gain the information they need to make faster and more accurate decisions. OpenSpace strengthens this approach by providing consistent, trustworthy site visibility that reduces rework, cuts unnecessary travel, and supports safety and quality.

The challenge

Linxon’s portfolio stretches from remote desert locations to dense urban rail corridors. Site conditions change rapidly, and teams often operate across different countries and time zones. Traditional photo documentation was inconsistent and stored across multiple devices, which created several challenges:

- Difficulty retrieving information when teams change

- Limited ability to support planners and safety engineers remotely

- Reduced transparency for leadership

- Increased travel requirements for site validation

A unified and dependable view of every site was needed to support teams working across regions.

The solution

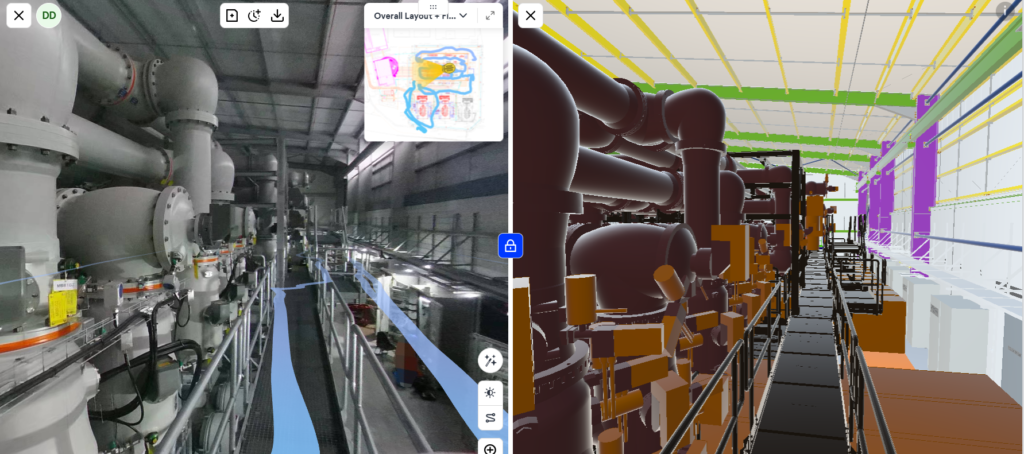

Linxon piloted OpenSpace on a major project in Saudi Arabia with a simple objective: replace scattered updates with structured, reliable data. Site teams captured 360‑walkthroughs every other day, giving global teams immediate access to accurate site conditions.

Project planning & controls

Remote planners and controllers review and track progress directly through OpenSpace and update schedules using real, time‑stamped visuals. Tasks that previously depended on weekly calls and manual follow ups are now completed within minutes, saving valuable time for both planners as well as site teams. “It is a go-to tool for my planners,” says Manikandan Rangasamy, Head of Planning AMEA. “They no longer have to run after people for progress updates. They just access OpenSpace and collect the information they need.”

HSE teams

Safety engineers use OpenSpace Field Notes to record observations pinned to digital floor plans. The structured workflow improves tracking, review, and resolution of issues. Engineers also use the platform to review each other’s sites, creating a stronger cross‑project safety culture.

Leadership

Senior managers gained dependable visibility of remote and hard‑to‑reach sites. They could verify progress, understand issues, and make informed decisions without the need for constant travel.

OpenSpace became a shared space for teams to understand site reality together. With clear value demonstrated, OpenSpace was rolled out across all active AMEA projects and extended to projects in Europe and North America.

“It is a go-to tool for my planners. They no longer have to run after people for progress updates. They just access OpenSpace and collect the information they need.”

The results

A single source of insight for every project gives Linxon the clarity to move faster, make better decisions, and stay aligned across continents.

Significant time savings

Managers reported a 10-15 % reduction in time spent on site along with a notable decrease in administrative hours. For planners, the ability to access real site conditions from anywhere on OpenSpace enables them to update schedules in minutes. As Manikandan explained, “Our planners collect site progress information they need quickly and effortlessly with OpenSpace.”

Unlocking expert knowledge across projects

Safety engineers began using OpenSpace Field Notes to flag potential issues and review each other’s sites remotely. Instead of relying on a single safety team per project, multiple HSE specialists can view the same capture, leave comments, and help identify risks. This peer-review effect strengthened safety awareness across Linxon’s entire portfolio.

Higher transparency and accountability

Teams and leaders share the same real‑time view of site conditions. This strengthens decision making and ensures consistent reporting even on remote projects.

More efficient coordination

Teams bring OpenSpace into weekly coordination meetings to verify site conditions and track progress, helping them ensure accurate planning and scheduling for the week ahead. This results in more productive weekly reviews as all participants can review project insights beforehand. This alignment minimises project delays and optimizes construction sequencing in execution.

A durable digital record

Every stage of construction is visually documented and easy to retrieve. The archive supports warranty discussions, claims, reporting, and handover while reinforcing long‑term project accountability.

With OpenSpace now embedded into their workflows, Linxon has a clearer, more consistent way to understand what is happening on every project, no matter the location. Remote teams stay aligned, planners move faster, and leaders make decisions with confidence.

Supporting Linxon’s sustainability goals

Digital tools like OpenSpace reduce travel, streamline workflows, and help teams minimise rework. These improvements support Linxon’s wider environmental commitments, including a 50 percent reduction in CO₂ emissions by 2030 and achieving net‑zero emissions by 2050.

By combining EPC expertise with AI solutions, Linxon is delivering infrastructure that is smart, safe, and sustainable. The adoption of OpenSpace is one of the ways the company is shaping a cleaner and more connected energy future.