Gap İnşaat, part of Çalık Holding, is advancing a company-wide digital transformation to improve transparency, coordination, and safety. This digital transformation agenda is led by CEO Levent Kafkaslı, whose vision for data-driven project delivery has guided the company’s technology adoption roadmap. On a landmark redevelopment project in Istanbul, the team adopted OpenSpace and connected captured reality data to their data stack to streamline health and safety workflows and reporting.

The challenge

On complex projects with many subcontractors and moving parts, keeping health and safety reporting both accurate and actionable can be demanding. At Gap İnşaat, inspectors traditionally relied on photos taken with mobile phones and notes shared through messaging apps. Weekly reports required a full day of manual work, which meant leadership and subcontractors often had to rely on delayed information that no longer reflected the situation on site.

For the company’s management team, having timely and reliable data was more than a matter of efficiency. It was essential for quickly identifying hazards, preventing risks from escalating, and making confident decisions about where to direct resources. As Azerhan Turan, Technology and Innovation Manager at Gap İnşaat explained: “Our health and safety reports used to take a full day to prepare every week. By the time they were ready, the information was already outdated.”

The solution

When Gap İnşaat introduced OpenSpace on site, the health and safety team quickly realized they could transform the way they documented observations. Instead of juggling phone photos, notes, and WhatsApp messages, inspectors now walk the site with a 360° camera and log issues directly in OpenSpace using OpenSpace Field Notes. Each note is automatically pinned to the floor plan, complete with images, descriptions, categories, and priorities. This gives every observation clear context and ensures that the responsible party knows exactly where action is required.

Because OpenSpace Field Notes are customizable, Gap İnşaat designed its own structured tagging system to capture details such as safety category, subcontractor, work type, and risk level. This flexibility allowed the team to shape OpenSpace around their existing workflows rather than change processes to fit the tool. Over time, these structured notes became the backbone of Gap’s digital safety and quality reporting.

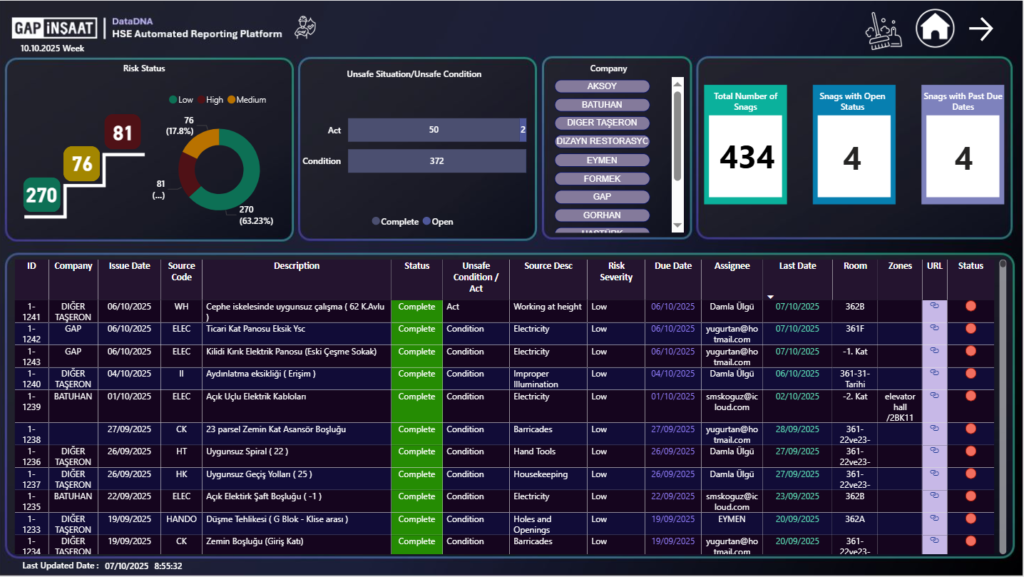

To make the information usable at scale, the Technology and Innovation team set up automated data flows from OpenSpace into their business intelligence environment. Field Notes data is exported to SharePoint and visualized in Power BI dashboards that refresh every morning at 08:00. For project leaders, this meant they could start each day with a clear, up-to-date picture of safety trends, subcontractor performance, and site progress. “With OpenSpace and Power BI working together, we no longer wait a week for reports. The information is there the next morning, ready for everyone to use,” explains Azerhan.

So far on the prestigious Istanbul project, the team has created more than 105 captures with over 1,200 Field Notes, providing a rich and detailed dataset that underpins their reporting and analysis.

What began with health and safety is now starting to expand into other areas. QA/QC and handover teams have begun trialling the use of Field Notes for inspections, snagging, and punch lists. While still in its early stages, this approach shows strong potential to create a single source of truth for all reality data, helping teams align their workflows more closely.

“With OpenSpace and Power BI working together, we no longer wait a week for reports. The information is there the next morning, ready for everyone to use.”

The results

With OpenSpace, Gap İnşaat now captures a complete visual record of site conditions and logs safety observations directly in the field. By pushing this structured data into their reporting environment, the team turned a previously time-consuming process into a faster, clearer, and more actionable system. Instead of spending hours compiling weekly reports, managers and subcontractors can focus on acting on insights drawn from fresh, trustworthy data.

The impact has been significant, with measurable improvements in reporting efficiency, safety awareness, and decision-making.

Reporting time reduced to near zero

Weekly manual reports that previously took a full day are now generated automatically. With dashboards refreshing each morning, the health and safety team saves at least four workdays per month, while management benefits from up-to-date insights instead of delayed weekly summaries. “Reporting used to eat up every Friday. Now the dashboards are ready the next morning, and everyone sees the same information,” says Azerhan.

Eightfold increase in safety observations

Health and safety observations rose from an average of 0.5 per day to 4 per day. The higher volume reflects not only greater on-site awareness, but also the ease and speed of logging issues with OpenSpace. By making it simple to capture observations, the team ensures more hazards are documented, which helps identify patterns and address risks before they escalate.

As Dilek Çelik, HSE Manager, explains: “Before OpenSpace, we were drowning in photos and messages from everywhere. It took hours just to understand what was happening on site. Now, everything is in one place, clear, visual, and reliable. We can finally focus on keeping people safe, not chasing data. We can also send instant notifications to the relevant managers and take quick action on any nonconformities.”

Faster issue resolution

With observations captured in one place, complete with images, location, and responsibility, managers no longer wait for a weekly report to take action. Corrective measures can be assigned immediately, accelerating the cycle from identification to resolution. “Before, we might only discuss an issue once a week. Now it’s visible right away, so the subcontractor can act the

same day,” explains Azerhan.

Stronger subcontractor accountability

Every note is tagged to the responsible firm and visible in dashboards that can be filtered by company and floor. This makes it easier to track follow-ups, verify progress, and hold subcontractors accountable.

For the team at Gap İnşaat, this is not just about oversight: it ensures problems are addressed at the right level, prevents delays, and strengthens trust across the project team. As a member of the project management team explains: “What truly changed for us was visibility. With OpenSpace we could finally see the exact situation on site — not just what was reported. When issues came up with subcontractors, we no longer debated whose version was correct; we simply looked at the record. That clarity saved time, prevented conflicts, and helped us solve problems before they grew.”

Better and faster decision making

Dashboards update at 08:00 daily, giving managers a clear view of current risks and progress at the start of each day. Having fresh, trustworthy data enables quicker interventions, smarter resource allocation, and the confidence to act without waiting for a weekly reporting cycle.

“What truly changed for us was visibility. With OpenSpace we could finally see the exact situation on site — not just what was reported. When issues came up with subcontractors, we no longer debated whose version was correct; we simply looked at the record.”

Looking ahead

Building on the success of the Istanbul project, Gap İnşaat is now preparing to extend the use of OpenSpace to upcoming work in Turkmenistan, including a fertilizer plant and two hospitals. The focus will remain on health and safety, QA/QC, and handover, with continued investment in structured tagging and live reporting to drive faster, safer delivery.